Coal Mill Production Down? Pay Attention to These 7 Castings

Coal mill production down? Check these 7 critical castings that often cause wear and failure to restore efficiency and minimize downtime.

Coal mill production down? Check these 7 critical castings that often cause wear and failure to restore efficiency and minimize downtime.

Explore essential wear parts of coal mill systems, including grinding rollers, liners, and other components critical for efficient performance.

Explore top coal-fired power plant coal mill wearing parts to improve durability, cut downtime, and enhance your power plant's performance.

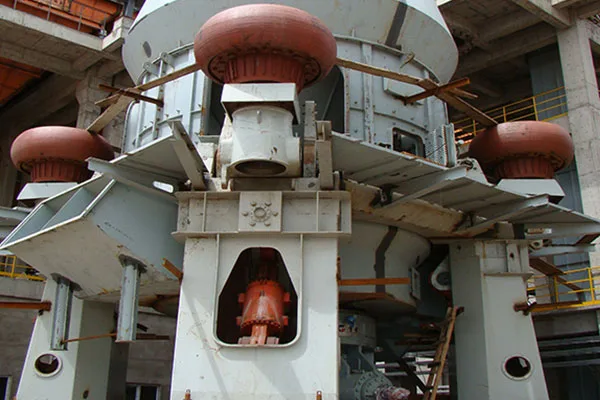

The coal mill grinding roller is the workhorse of pulverizing raw coal into fine powder for combustion.

Discover how a coal mill in cement plant enhances fuel efficiency, combustion control, and consistent clinker production.

Grinding mill machine parts are more than just components—they're the foundation of your milling system success.

Efficient material handling systems designed to improve workflow, safety, and productivity in industrial and warehouse environments.

At their core, feeding machines are automated systems designed to supply materials or parts to a production line with precision and consistency.

At its heart, an industrial bucket elevator is a continuous-loop system. Buckets are fixed at regular intervals to a traction medium—either a rubber belt or steel chain.

This design allows for simultaneous grinding and drying, making vertical coal mills particularly effective for processing coal with high moisture content.