Huifu is a professional manufacturer that supports mass customization of coal mill accessories and can produce a variety of mill accessories. If you want to know more, please contact us.

Table of Contents

Introduction

If you work in industries such as power generation, cement production, or mining, you know that coal mill castings are critical to the performance and service life of your equipment. These components are the backbone of efficient coal grinding, and choosing the right ones is essential to ensuring smooth operation and avoiding costly downtime.

This guide will walk you through everything you need to know before making a purchase, from materials and manufacturing processes to maintenance and supplier evaluation.

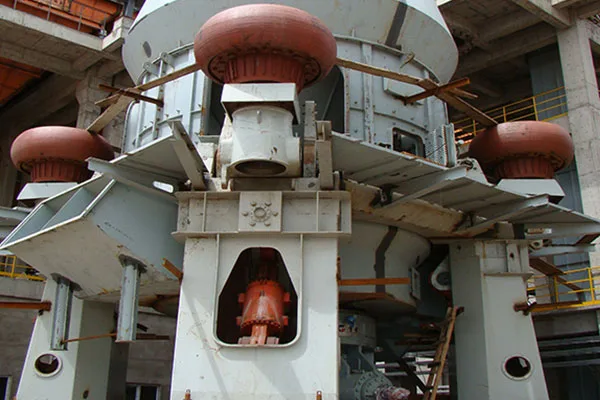

Understanding Coal Mill Casting Parts

Coal mill casting parts are specifically designed to withstand the abrasive, high-pressure environment inside a coal grinding system. They are typically produced using high-quality alloys such as high-manganese steel, chromium-molybdenum steel, or heat-resistant alloys, each selected for its unique performance attributes.

In most operations, these parts include grinding rollers, grinding rings, liners, housings, and classifier blades. Each plays a unique role in ensuring consistent grinding performance and reducing wear-related failures.

Types of Coal Mill Casting Parts and Their Applications

Not all coal mills operate under the same conditions, so it’s essential to match the part to the specific demands of your process.

| Part Name | Main Function | Common Material | Typical Service Life* |

|---|---|---|---|

| Grinding Roller | Applies pressure to crush coal | High-chromium cast iron | 8,000-10,000 hours |

| Grinding Ring | Works with a roller for pulverization | High-manganese steel | 10,000-12,000 hours |

| Liner Plate | Protects mill housing | Chromium alloy steel | 12,000+ hours |

| Classifier Blade | Separates fine coal from coarse particles | Heat-resistant steel | 6,000-8,000 hours |

| Housing Components | Structural protection and support | Alloy cast steel | 15,000+ hours |

*Based on industry reports and manufacturer specifications. Actual lifespan varies by coal type, operational load, and maintenance.

Key Factors to Consider When Selecting Coal Mill Casting Parts

Material Selection

The choice of material determines wear resistance, heat tolerance, and impact strength. High-manganese steel, for example, hardens under impact, making it suitable for heavy-duty grinding environments, while chromium alloys offer exceptional abrasion resistance.

Manufacturing Quality

High-precision casting techniques, such as resin sand casting or lost foam casting, ensure better dimensional accuracy and surface finish, which directly impacts installation ease and operational stability.

Compatibility with Existing Equipment

Even the highest-quality part will fail prematurely if it does not fit your specific mill model. Always confirm dimensions, mounting features, and tolerances before purchase.

Supplier Expertise and Support

Working with a supplier who understands both the technical requirements and the operational challenges can save you from costly mistakes. Look for suppliers with proven track records in power plants, cement plants, and mining operations.

Maintenance and Performance Optimization

Proper maintenance extends the lifespan of coal mill casting parts and ensures consistent mill output. Regular inspection schedules should include checking for surface cracks, uneven wear, and dimensional changes.

Some best practices include:

- Rotating or reversing grinding components to even out wear.

- Using correct lubrication to reduce friction and heat buildup.

- Keeping coal feed consistent to prevent overload on grinding parts.

- Training operators on optimal loading procedures to reduce shock loads.

Common Problems and How to Avoid Them

Despite their durability, coal mill casting parts can face premature wear or failure if operational parameters are not maintained. Common issues include:

- Abrasion due to low-grade coal: Using coal with high ash content increases wear.

- Thermal stress cracks: Caused by sudden temperature changes during shutdown/startup cycles.

- Improper installation: Leads to uneven contact and accelerated wear.

Addressing these issues early can prevent costly downtime and replacement expenses.

Conclusion

Coal mill casting parts are not just replaceable components; they are essential for maximizing productivity, reducing operational costs, and ensuring safety. By carefully evaluating material quality, manufacturing precision, compatibility, and supplier expertise, you can make informed decisions that protect your investment for years to come.

FAQ

How often should coal mill casting parts be replaced?

Replacement intervals depend on operational load, coal quality, and maintenance. High-quality parts can last anywhere from 8,000 to 15,000 hours.

Can worn parts be repaired instead of replaced?

Minor wear can sometimes be repaired through welding or resurfacing, but heavily damaged parts should be replaced to avoid safety risks.

What’s the most important factor in selecting parts?

Material quality and compatibility with your mill design are equally critical to achieving long service life.