Medium Plate Feeder Equipment

Medium Plate Feeder Equipment

Heavy plate feeder is a highly efficient conveying equipment, mainly used for continuous and uniform feeding from storage bin to crusher, conveyor or other machinery, and can also be used for short-distance conveying of materials with large block size and density. It can be installed horizontally or tilted, and the tilt angle of tilted installation can reach 25°. It adopts variable frequency motor speed regulation or hydraulic motor speed regulation, and can be controlled and interlocked with the receiving device to meet the process requirements. It is widely used in mining, metallurgy, building materials, chemical industry, coal and other industries. Heavy plate feeder has simple structure, convenient use, easy maintenance, labor saving and durability.

Medium Plate Feeder Equipment: Technical Features

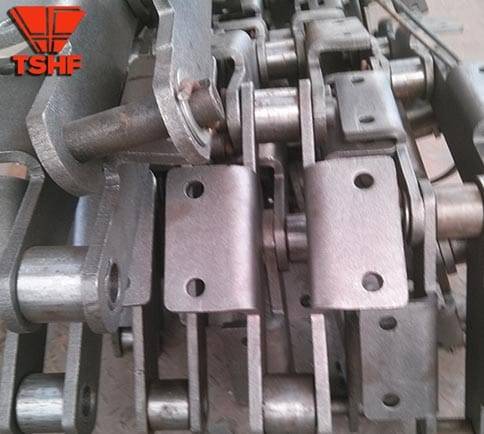

1. It is mainly composed of chain plate device, tensioning device, driving device and spindle device.

The motor rotates, and the main shaft is driven to rotate through the transmission shaft and driving device. The sprocket and chain are installed on the spindle device, and the chain plate on the chain is driven to make linear motion through the device. The chain is equipped with a material bearing trough plate. The linear motion of the chain plate brings the material evenly to the trough plate of the chain and conveys it forward to achieve the purpose of conveying the material. This design enables the heavy-duty plate feeder to complete the material conveying task stably and efficiently, and performs well in various industrial environments.

2. Advanced manufacturing process

Customized design: The conveying trough is welded by the bearing plate and the side plate. The bearing plate is made of low-alloy carbon structural steel 16Mn hot-pressed and has a double arc structure. After the conveying trough is assembled, the gap between the overlapping parts is less than 2mm. At the same time, our company has 3 professional design engineers for plate feeders who can design drawings according to the parameters provided by your company.

Manufacturing process: The conveying trough of our medium-sized plate feeder is welded by the bearing plate and the side plate. The bearing plate is made of low-alloy carbon structural steel 16Mn hot-pressed and has a double arc structure. After the conveying trough is assembled, the gap between the overlapping parts is less than 2mm. The driving sprocket is made of alloy steel 40Cr, which is tempered and the surface of the gear teeth is quenched to make it have excellent strength and wear resistance.

The frame is welded by H-shaped steel, with a reasonable structure, which can make full use of the rigidity and strength of steel. All steel is shot blasted and rust-proofed. After rust removal, anti-rust primer is applied within 24 hours to protect the metal surface that has been rusted. After the finished product, anti-rust paint, intermediate paint and topcoat are applied once.

Quality control: Strictly operate in accordance with the requirements of the 9001 quality management system.

3. Strict inspection

Each product is inspected before delivery, including material testing and physical performance testing, to ensure functional performance.

Performance indicators

1. All spindles, supporting wheels, chain plates, and drive devices should rotate flexibly after installation. All bolted joints must be firm and reliable. Before the newly installed conveyor is officially put into use, it should be tested for 2 hours of no-load and 8 hours of load.

2. The site and users must be trained before use and safety training to avoid safety accidents.

3. The normal use of the supporting wheel and chain plate can reach 30,000 hours, and the life of the frame part can reach 10 years.

Application

It is suitable for mining, metallurgy, building materials, chemical industry, coal and other industries, and is used to transport materials of different particle sizes and different bulk densities.

| Number | Term | Unit | Data | Remark | |||||||

| 1 | Chain plate width | mm | 650 | 800 | 1000 | 1200 | 1250 | 1400 | 1500 | 1600 | |

| 2 | length | m | 3-20 | ||||||||

| 3 | capacity | t/h | 270 | 310 | 360 | 600 | 600 | 800 | 1000 | 1500 | |

| 4 | angle | ° | 0-23 | ||||||||

| 5 | power | kw | 3-55 | ||||||||

| 6 | Speed | m/s | 0.05-0.1 | Speed range 1:10 | |||||||

| 7 | bulk density | t/m³ | 0.5-2.5 | ||||||||

| 8 | granularity | mm | ≤100 | ≤300 | ≤450 | ≤600 | ≤600 | ≤650 | ≤700 | ≤800 | |

Why choose Huifu Company?

Choose Huifu Company for its comprehensive solutions in machinery manufacturing, processing, and maintenance, backed by over ten years of industry experience. Their one-stop services, including custom design and production of non-standard products, meet diverse needs efficiently. With a strict quality control system, they ensure every product is reliable and safe. Their professional team provides robust technical support, while their innovative patents, such as mobile reversible belt conveyors and foundry sand recycling processes, demonstrate their commitment to industry leadership. Huifu’s customer-first philosophy ensures personalized services and long-term partnerships. Partner with Huifu to achieve project success with high-quality products and dedicated support.